Content on this website may not be accurately translated due to the limitations of the translation software from Google Translate. The official text is the English language version of the website. Any discrepancies or differences created in the translation are not binding and have no legal effect. If questions arise in relation to the accuracy of the information mentioned on the translated website, please refer to the English version of the website.

Rethinking packaging for edible oils

In previous blogs I have argued that brands’ sustainability goals should be revisited to make sure we adapt to the growing knowledge around climate change and that we should level up to focus on circularity as opposed to just recyclability.

This requires us to think differently and make bolder decisions. That’s easy enough to say, but it’s not always easy to know where to start or what actions are the right ones to take. Let me offer a practical use case – edible oils.

According to Euromonitor International, retail sales of liquid pour edible oil containers under 750ml consist primarily of plastic and glass. For larger containers over 750ml, about 5% are made of metal. Most large volume oils, especially those at lower price points, are packaged in plastic. In a nutshell, glass and plastic dominate when it comes to edible oil packaging.

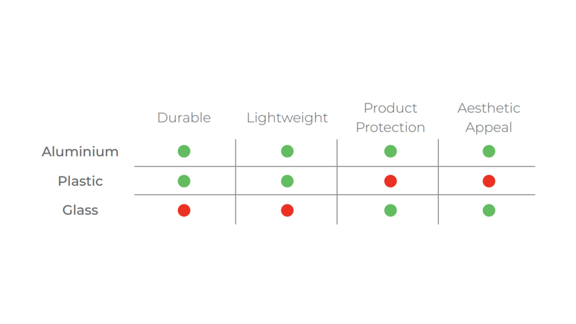

Metal’s protective properties are well established when it comes to food. In addition to providing robust protection against the occasional drop and bump, metal also keeps out both sunlight and oxygen, the two primary drivers of premature quality degradation in food stuffs. The negative effects of sunlight was outlined in an article by The Economist earlier this year where the magazine showed that the “smellprint” of white wines shipped in clear glass bottles suffered after just one week when exposed to light. Metal’s protective qualities mean it should be the go-to packaging option when it comes to delicate products like wine and edible oils. So, why is metal not seen as an option by many brands when it should be the primary contender? I would argue that tradition plays an important role.

Products like wines, spirits, and edible oils are steeped in culture and tradition. Traditional ways of harvesting, aging, and packaging are revered and, in many cases, go back centuries. The perception is that this is how it’s always been done, so it must be the right way to do it.

Brands also worry that changes in packaging or brand visuals may cause consumers to change their perception of a brand or not recognize it on the shelves. While I agree that significant brand changes must be carefully managed, changes can also result in positive effects and open up new business models and markets.

For example, Trivium has worked with several spirit brands that have embraced refill business models where metal packaging plays an integral part. Many of our wine producing customers have also adopted metal bottles for their smaller sizes to appeal to consumers who want sustainable and robust packaging that works for the beach, on the picnic, at the concert, and so on.

When it comes to standing out on the shelves, metal offers high speed in-line printing that enables the packaging to take on nearly infinite graphical effects without the need for labels. Brands can use the entire surface of the bottle to achieve the desired look without ever adding paper or plastic components. This will both differentiate the look of the bottle and remove unnecessary materials to simplify recycling for the consumer. Metal can also provide a premium look and feel that are right for many edible oil brands.

Breaking with tradition can feel like a challenge, but there’s far more to be gained than lost and the time is right.

We know customers want more sustainable packaging. Of the 15,000 end consumers surveyed in our 2022 Buying Green Report, 70% identified themselves as environmentally aware. A total of 74% expressed an interest in buying products in refillable packaging, and a whopping 86% of consumers younger than 44 said they are willing to pay more for sustainable packaging. In addition, plastic packaging is under pressure and consumers are exposed to strong visuals and data that show the effects of plastic waste.

Metal has strong sustainability credentials. As an infinitely recyclable material with the highest recycling rate across regions, metal is proven to be the most environmentally sustainable substrate for a truly circular economy. In addition, adopting a refill and replace system has the potential to eliminate all single use plastic parts entirely. In a refill and replace system, consumers purchase a mono-material bottle of oil with a reusable spout attachment to reuse with the next purchase. In this way, consumers get the benefit of a premium pour spout and can replace the bottled oil with no wasted material. The empty aluminum bottles get recycled and returned to the raw material stream which in turn provides continuous recycled content to the supply chain.

As the importance of finding sustainable alternatives to single use packaging grows, the pressure for brands to act is increasing. As the whole world looks for sustainable materials and solutions, the supply chain adjusts, and brands have a window of opportunity to stand out as sustainably mindful.

Now is the time to reconsider when and how we use metal packaging when it comes to edible oils. By converting to metal packaging in segments where current packaging fails to meet today’s issues, brands have the opportunity to offer a better product and brand experience to consumers, drive brand differentiation, new product adoption, and brand loyalty, all while meeting sustainability goals and ensuring a sustained future for years to come. Sometimes breaking with tradition can be the right thing to do.