Content on this website may not be accurately translated due to the limitations of the translation software from Google Translate. The official text is the English language version of the website. Any discrepancies or differences created in the translation are not binding and have no legal effect. If questions arise in relation to the accuracy of the information mentioned on the translated website, please refer to the English version of the website.

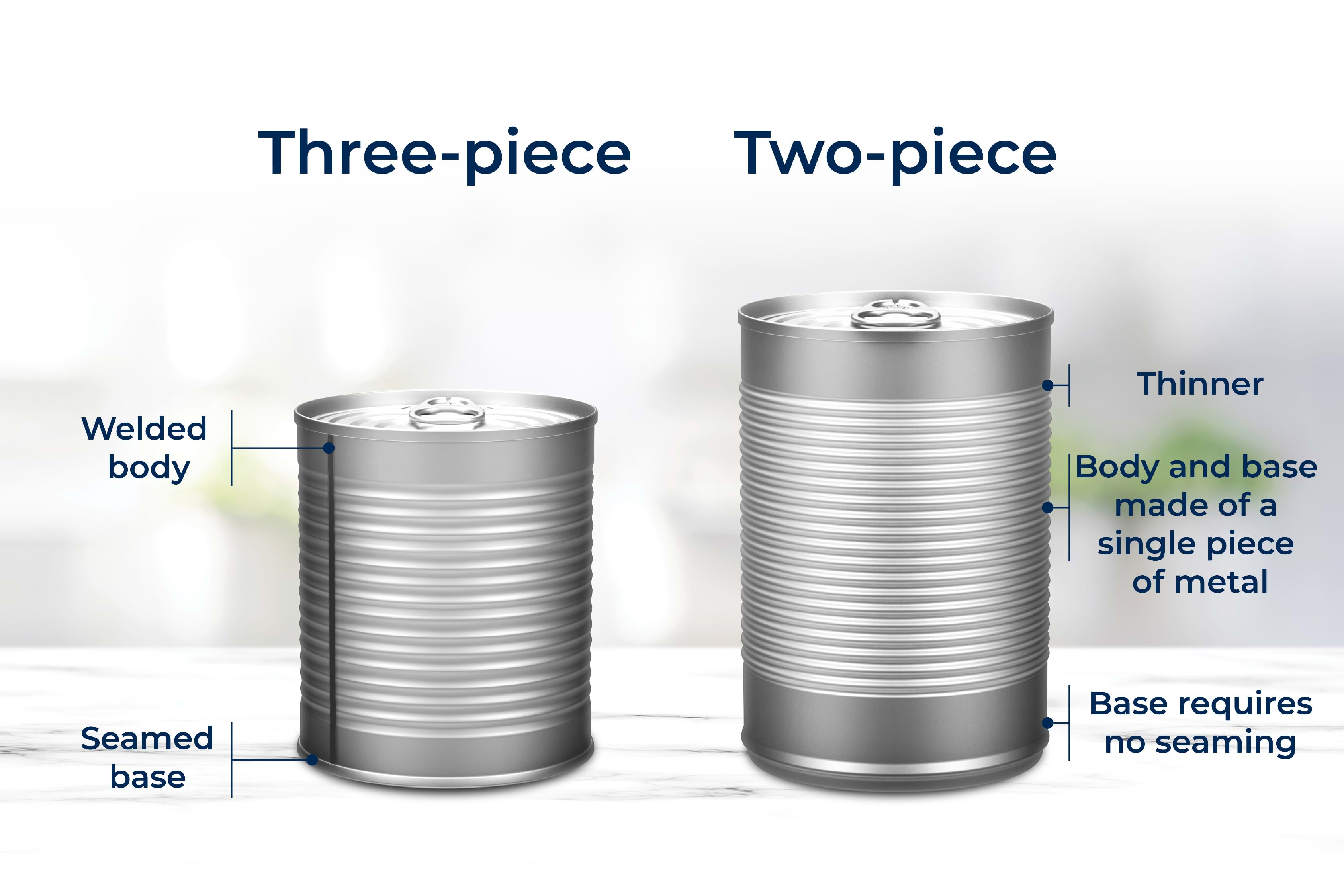

Three Piece Cans

Trivium’s three-piece cans are suitable for a wide variety of applications including food cans, nutrition cans, paint cans and tinplate aerosols.

Three-piece metal cans provide superior protection to extend shelf life and reduce food waste. These cans allow for a wide range of flexibility in height and diameter and can be directly printed on. When desired, these cylinder cans can be shaped, giving the can a unique design.

Our bold printing, graphics and shaping options help your brand differentiate in crowded categories.

Through standard and customized shapes and distinctive graphics and finishes, we deliver a solution in which the can and graphics work hand-in-hand to maximize impact.

Our full colour printing machines use the latest technologies to deliver distinctive decorative effects. They include NoVar inks that allow matte and gloss on same can, soft-touch inks for a rubberized can feel and metallic flake and pearl base coat effects.

Butcher’s Pet Care, a leading British pet food manufacturer, is committed to protecting the health of dogs with naturally nourishing food, and the environment with sustainable packaging.

Butcher’s has replaced the plastic shrink-wrap packaging on its multipack cans with recyclable and biodegradable cardboard, while retaining its commitment to metal cans produced by Trivium. In fact, the sustainability of the cans is an important part of Butcher’s environmental pledge, which states: “…Our cans are infinitely recyclable forever. These metals can be easily and sustainably turned into new materials, like car parts, bicycles or even more cans!”

“We know that reducing plastic packaging waste is a key concern for consumers,” said Rachel Collinson, Director of Food for Dogs at Butcher’s Pet Care. “We also appreciate the environmental credentials of the metal can, which is so easy to take for granted.”