Content on this website may not be accurately translated due to the limitations of the translation software from Google Translate. The official text is the English language version of the website. Any discrepancies or differences created in the translation are not binding and have no legal effect. If questions arise in relation to the accuracy of the information mentioned on the translated website, please refer to the English version of the website.

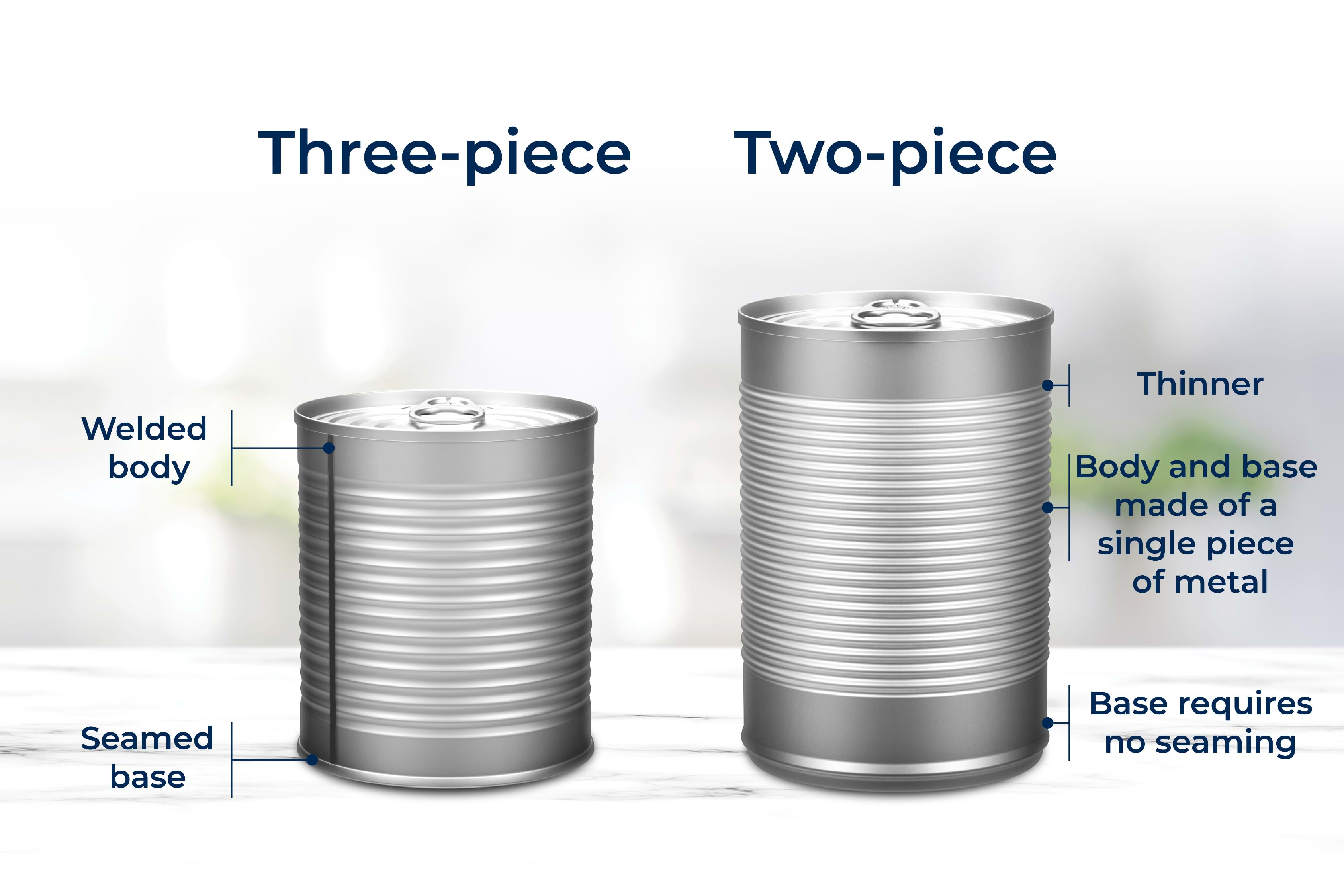

Two Piece Cans

Trivium’s two-piece cans are ideal for food. Two-piece metal cans provide superior protection to extend shelf life and reduce food waste.

These cans can be quickly produced and use the metal material in an efficient way, contributing to their low cost.

Metal packaging presents a premium image to your customers and is an ideal canvas for brand and product graphics.

Our sophisticated shaping capabilities and custom graphics and finishes deliver impact in ways that plastic packaging simply can’t. For example, we can offer NoVar inks that allow matte and gloss on same package, soft-touch inks for a rubberized feel and metallic flake and pearl base coat effects.

Our brand-elevating innovations not only improve the sustainability of your packaging but also offer a premium look and feel. And, with a growing range of products, we’re making an impact on more industries than ever before. Our metal packaging provides sustainability on all levels.

- 100% recyclable, infinitely, and because of well-established recycling channels, metal packaging has one of the highest recycling rates, with a global average of 60-70%

- Lightweight and recycled content options are available

- Metal packaging provides a superior 360° promotional billboard with attention-grabbing advanced graphics for optimal brand awareness, giving space to communicate the sustainability credentials of your package to your consumers

- Provides robust product protection

- Durable material offering resilient protection

- Strongest UV and oxygen barrier, rust-proof

- Aligns with consumers’ "push from plastic" and desire for a more sustainable packaging

Packaging innovation brings gourmet taste anywhere from outer space to high-speed trains. Hénaff picked the aluminium can developed by Trivium to preserve the freshness of a delicious dessert - the Apple & Fondant Galette - in any environment. Tested and approved by astronauts on the International Space Station, Hénaff’s products made their way on board TGV INOUI trains.

With support from our R&D Centre, Trivium’s aluminium can plant in Cuxhaven, north Germany, succeeded in producing the world’s lightest aluminium seafood can.

The shaped Dingley can achieves a wall thickness of 0.170mm – a significant advance over its nearest competitor at 0.215mm. Despite being extremely light in weight, it retains the stability of a standard can and may be fitted with an Easy Open® ring-pull lid.